Understanding the Dilling Equipment Bucking Machine: Key Considerations for Growers

Aug. 18, 2025

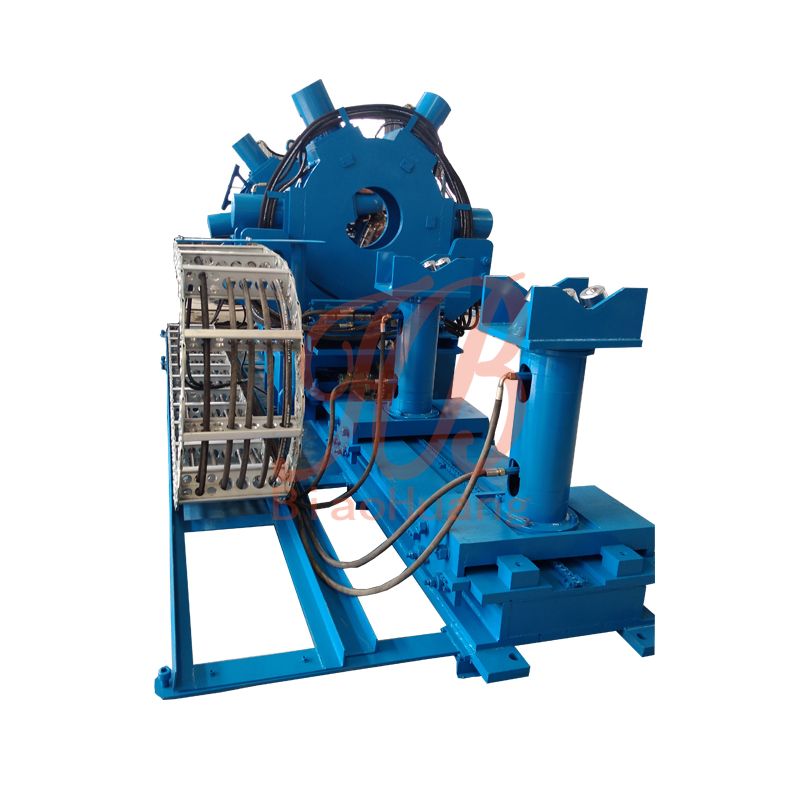

The Dilling Equipment Bucking Machine has become a valuable tool for commercial growers and processors looking to increase efficiency in handling large harvests. While its ability to save time and labor is undeniable, users often raise questions about how it impacts workflow, product quality, and maintenance. Below we address five of the most common concerns, providing practical insights for anyone considering this equipment.

Why use a bucking machine instead of hand bucking

Hand bucking has long been the traditional approach, offering growers complete control and the ability to carefully inspect each plant. However, when working with large volumes, this method quickly becomes time-consuming and physically demanding. A bucking machine, such as the model from Dilling Equipment, allows operators to process multiple stalks per minute, cutting labor time dramatically. For many businesses, this efficiency directly translates into higher productivity and reduced labor costs. Still, hand bucking remains valuable for smaller batches or when top-shelf flower requires extra attention.

Does moisture level affect the bucking process

Moisture content plays a critical role in how effectively the machine performs. When plants are processed while still slightly moist, the buds maintain their structure and can be separated cleanly. On the other hand, overly dry material may shatter during processing, leading to excessive breakage and loss. This means timing the harvest and adjusting drying schedules is essential for optimizing results. Many operators prefer bucking before full drying, allowing the machine to work efficiently without compromising the integrity of the product.

How easy is maintenance and cleaning

Ease of maintenance is one of the practical concerns with any large piece of processing equipment. Bucking machines handle plant matter that inevitably produces debris, so regular cleaning is necessary. The Dilling Equipment model is designed with removable plates and accessible components, making it quicker to clean compared to earlier designs. Routine upkeep not only extends the lifespan of the machine but also ensures consistent performance during long harvest cycles. By scheduling short cleaning breaks, operators can keep downtime to a minimum.

Does machine bucking affect bud quality or trichomes

Quality preservation is a recurring question for growers who care deeply about the final product. While bucking machines are designed to minimize damage, the high-speed process may still cause some trichome loss compared to hand bucking. For businesses focused on premium flower, this is an important trade-off to consider. However, for bulk processing where speed outweighs minor quality loss, the machine proves highly effective. Many operators use a hybrid approach—machine bucking the majority while reserving select buds for hand processing to ensure top quality.

When should hand trimming be prioritized over machine use

Even with the efficiency of a bucking machine, there are scenarios where hand trimming remains the preferred choice. Premium buds destined for specialty markets or customers who value visual perfection often benefit from careful manual handling. Machines excel at processing large volumes quickly, but selective handwork ensures that the highest-grade material maintains its full appeal. A balanced strategy—machine processing for general product and hand trimming for showcase batches—allows growers to maximize both efficiency and quality.

Conclusion

The Dilling Equipment Bucking unit offers a powerful solution for streamlining harvest operations, but its success depends on how it is used. By considering factors such as moisture levels, maintenance routines, and balancing machine efficiency with hand trimming for premium quality, growers can achieve the best outcomes. For many operations, this combination of speed and flexibility makes the machine an essential part of modern cultivation.

10

0

0

All Comments (0)

Previous: Top Pcb Smt Equipment for Efficient Electronics Manufacturing

Next: Essential Guide to Surface Mount PCB Labeling Techniques

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments